The various operating systems of the forklift are connected by many components and work together to maintain the normal operation of the forklift. Excessive dust will cause blockage of parts and affect the operation of various systems of the forklift.

Minor failures may cause forklift operation problems, and major failures may cause engineering accidents. Therefore, we should clean the parts of the forklift regularly. At the same time, we can also replace some wearing parts.

Now let me talk to you about the cleaning of forklift parts and batteries.

1. For the cleaning of some metal parts of forklifts, we usually use cold washing and hot washing methods.

1. The cold washing method is to use kerosene. It is quick. After washing with light diesel or gasoline, blow dry with compressed air. The equipment required for this cleaning method is very simple. The operation is also very fast.

2. The hot washing method is to clean with alkali solution and heat the solution. Then the parts are soaked and taken out, rinsed with clean water, and then dried with compressed air.

In order to prevent corrosion of aluminum alloy parts, it cannot be cleaned with a solution containing a large amount of sodium hydroxide.

2. For the cleaning system sealing ring of some non-metal forklift parts on the forklift, use alcohol.

The cleaning of rubber parts, such as brake cups, turpentine or brake fluid. Do not use kerosene.

Rubber ring. It should be cleaned with hydraulic gasoline or alkaline solution to prevent swelling and deterioration.

The clutch friction plate and brake friction plate can not be boiled and washed with alkaline solution, and should be cleaned with a little gasoline.

Leather parts (such as oil seal aprons, etc.) are generally cleaned with a dry cloth.

3. The common dirt on forklift parts also has a black solid-it is gradually formed under high temperature and high pressure, and firmly adheres to the surface of internal combustion engine pistons, cylinder liners, cylinder heads and other parts. The texture is extremely hard.

Carbon deposits must be removed during repairs. In order to ensure the normal operation of the forklift, the carbon deposits on the parts must also be removed regularly. We usually clean up this kind of dirt in two ways:

1. One is physical cleaning, that is, scraping with a spatula, spatula (or with a bamboo chip), metal brush, etc. This method of manually removing carbon deposits is inefficient and difficult to remove. If you are not careful, it will damage the parts.

2. There is another way to remove carbon deposits by chemical methods.

The solution for removing the carbon deposits of internal combustion engine parts is prepared: then soak the carbon deposits of the parts in the cleaning solution.

If there is a heating device, it can easily soften the dirt, and the solid dirt can be easily peeled off after the soaking is over.

The battery of an electric forklift can be washed with water, but water cannot enter the battery cell. Try to hang it out and wash it to avoid water entering some parts of the forklift. When forklift batteries have been used for a certain number of years, oxides will be generated, and resistance between battery cells will be generated. Cleaning is necessary.

The above is about the cleaning of forklift parts and batteries. In daily work, more maintenance can make the forklift use longer and reduce the loss of the forklift. I hope it will be helpful to everyone.

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

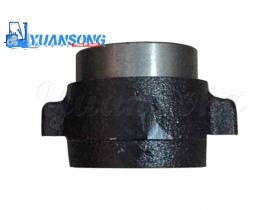

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001