-

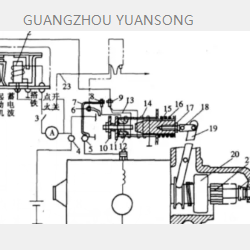

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan TD27 H20-2 Clutch Drum 31511-51K00

Nissan forklift H20-II;H25;TD27;BD30 F20-30Clutch Drum.

-

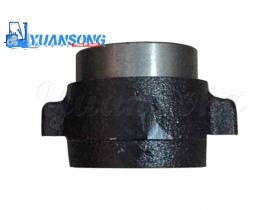

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

CT5400SA Bearing Clutch Release 3EB-10-31930 Komatsu C16 4D94LE

Komatsu:4D92E-C20 FD10-18;4D94E-C15 FD20/25;4D94LE-C16 FD2.

-

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota 5F 14Z 1FZ Piston Clutch Drum 32152-33900-71

Toyota forklift 5FD 14Z;5FG 1FZ 3F Piston Clutch drum.

-

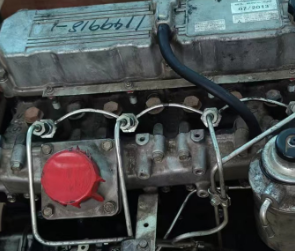

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu FD30-12/14 Support Clutch Release Bearing 3EB-10-31120

Komatsu:4D94E-C12;C12 is matched with 4JG2/C240/H15/H20/H25;4D94E-C14 FD2.

-

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

Toyota 8FD30 Wheel Brake 47040-26600-71/LH 47030-26600-71/RH

3Z 8FD25;2Z 8FD20 Wheel Brake of Toyota forklift parts.

-

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16 Brake Drum 3EB-21-52320

Komatsu FD25-16/4D94LE BRAKE DRUM.

-

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Toyota 5/6/7FD15 1DZ BRAKE DRUM 42431-13600-71

Made in the taiwan authorized by toyota.

-

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota Brake Master Cylinder 47210-23321-71 Aisin BMW-001

Toyota:2Z 7FD30;4Y 7FG20;7FB18;1DZ 7FD20-25;3Z 8FD25;2Z 8.