We focus on providing high-quality, long-life and reasonable price products, so we independently created the forklift parts brand "KOVO" and the forklift tire brand "BGO". As the official distributor of Aisin, we have close cooperation with Nikki, KYB, SHIMADZU, AISAN and other famous parts brands to ensure that we provide our customers with first-hand prices. We have extensive contacts and in-depth cooperation with more than 200 forklift parts manufacturers to provide our customers with a variety of choices and the best prices.

-

Transmission parts

Transmission partsthe Transmission parts devide into MTM and ATM,ATM constitute with trasmission teeth assy Torque Converter Input Plate Charging Pump and other parts ,MTM constitudte with trasmission teeth assy and gear shaft.

Shop Now -

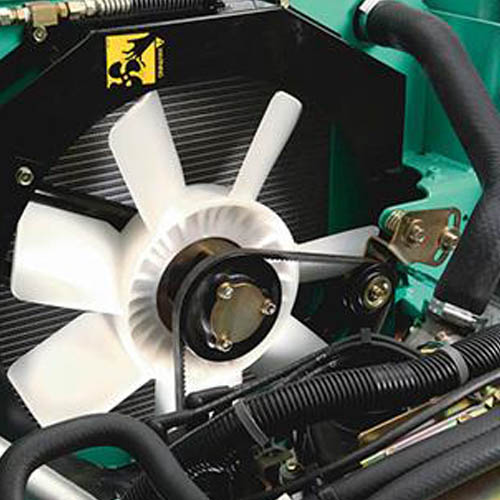

Cooling System

Cooling Systemcooling system means: forklift parts system(cooling for the engine) constitute with Radiator、Fan、Hose,Radiator、Water Pump、Thermostat、radiator coolant and other parts .

Shop Now -

Steering System

Steering Systemsteering system is chassic transmission parts ,include Front Axle、Hub,Rear Axle、Steering Cylinder、Cylinder rear axle wheel rim、Steering Knuckle and so on

Shop Now -

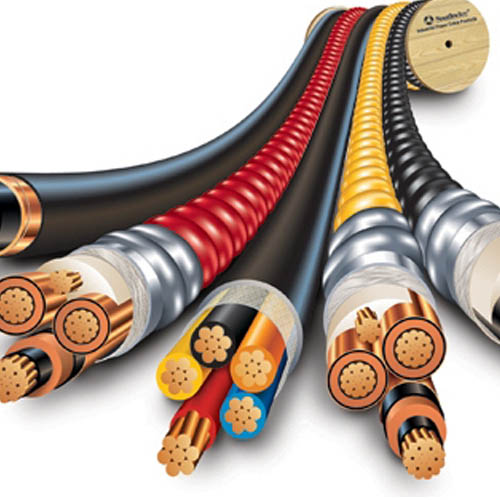

Electrical System

Electrical Systemforklift Electrical System parts is all over the forklift ,main parts and vulnerable parts have Alternator Distributor Switch Starter Switch Assy Combination Relay Speed Sensor

Shop Now